1. Scope and Compliance: Define clearly the purpose and functions of this skid system. Here you will define what chemical it is pumping, what would be the flow and pressure of that chemical. What is the function of the chemical in the overall process? How critical it is and if it requires redundancy and what is the duty cycle. Also briefly describe the environment where the system is located and where it will be injecting. Depending upon the application, industry and environment there will be a list of compliance requirements. Make a complete list of pump, environmental, structural and locational compliances.

2. Location / Structural & Power: Both the location of the facility and the location of the system within the facility are major factors that need to be surveyed. The structure on which the system will be mounted and structural requirements of the skid itself needs to be defined based upon the location and its vulnerabilities. The availability and feasibility of power which in most cases would be electric and in some cases would be solar or pneumatic would determine the motive system driving the injection pump.

3. Chemical and Performance Specifications: Choice of material of construction for the wetted parts and its corrosion resistance is not just a reliability issue but also a serious safety concern. The rate at which the chemical needs to be injected directly impacts the effectiveness of the process. The pressure at which the chemical needs to be delivered would dictate the strength of the pipes and power for the driver / motor for the pump.

4. Control System: This is the brains of the system. The control system turns the pumps or valves on and off depending upon the verification of the actual flow delivery. Here we determine the sensors and other measurement devices and how they will work together to deliver the performance required for optimum process efficiency.

5. List of major components and procurement planning: Now we are ready to put together a detailed Bill of Material for the skid based on the answers of the questions above and the specifications from the customer or the engineering company. This is also where the budgeting and costing of the system is verified. The components are sourced and their deliveries matched to the schedule of the project.

6. Assembly, Reliability & Testing: Most systems are often assembled in a separate manufacturing facility and then delivered to the project site. Sometimes the system is delivered in modules and assembled at the site. And there are occasions where the entire assembly is done at the site. A plan needs to be drawn for preliminary leak and electrical testing for each component and as a system.

7. Transportation / Installation and Start Up: The skid system needs to be designed for easy and safe transportation. There needs to be close coordination with the site for delivery, installation and start up.

Scope and Compliance

For any project it is important to get everyone on the same page about the purpose and scope. It is just as important if not more important to define what the system is not designed to do as it is to define what it is designed to do. Often there is what is known as engineering creep that gets in and we end up with a system that is way over-designed and over-budget.

Start with a simple definition of purpose. It could be as simple as “to deliver precise amount of anti-scalant chemical to prevent scaling in the system pipes”. Then we can add what redundancies we intend to have in the system. For example we can state that there will be one main pump and one stand by. There could be similar redundancies incorporated in power source, motive driver and main controls and sensors for example. It is important to define the control system and how it will communicate with the broader process controls and sensors at the site. A quick consideration of the size and survey of the location is often useful at this stage.

If the system is being used in Oil and Gas industry often compliance with API standards is mandatory. Depending upon the location of the system Class 1 Div 2 explosion proof electrical devices including motors and valves would be required. It is useful here to work with a checklist of potential hazards and industry standards to come up with a list of relevant compliances. This is also the opportunity to determine whether quality procedures and QMS are a requirement for all vendors.

An important detail that often gets omitted here is the specific requirement for compliance testing and documentation. This avoids delays and budget busting if these are not clearly defined at this stage.

Location, Structure and Power

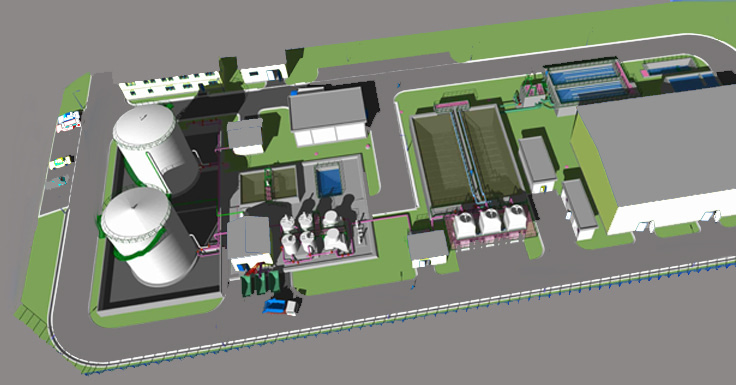

One of the foremost and important considerations for chemical injection skid system is its location, whether it is going be indoors or outdoors? Whether the environment requires all Explosion Proof motors and electricals? Does the ambient temperature need to be taken into consideration? etc. The location of the system and its proximity to the main chemical storage tank and day supply tank are extremely important factors. If the chemical is drawn from a tank that is too far that creates suction and priming issues with pumps. There have been systems which require special consideration for extremely hot ambient temperatures as well as locations in Alaska where the temperature drops to extremes on the low side. This could require space heaters or even heated pumping chamber.

In critical applications the earth quake hazard needs to be considered and the system needs to be mounted on special structures to conform to the seismological standards. International Building Codes (IBC) dictate the seismic specifications and testing requirements for critical facilities such as hospitals, nuclear power facilities etc. Presence of corrosive fumes in the air or potential for exposure to liquid chemicals also determine the chemical protection of the system components and structures. If the skid systems needs to be mobile, then it warrants many other related considerations. Will it be on a trailer? Or will it be on the vehicle itself. The power source needs to be re-evaluated if it is going to draw power from battery or a PTO. Such systems also have chemical tanks that are smaller and the whole system needs to be very compact and power efficient. If the system is located on a remote offshore rig then it needs to consider the transportation and commissioning at such locations.

There are pumps, valves, flow meters and controls on a chemical skid system that needs power to run. If multiple power options are available choosing the proper source requires analysis of environmental impact, cost of energy and the power amperage required to run all components in the system. Often we are limited to one power source that is available and it needs to be used in the most optimum way. Electrical is not the only power option though to power an chemical injection system. Pneumatic powered systems use compressed air or gas. If compressed gas is used there needs to be a gas recovery system after it has powered the injection system. In remote areas Solar power is another possibility, however the power draw form this source cannot be too high due to availability and storage of this kind of power.